IQF Tunnel Freezers and Chillers Range

The versatile IQF tunnel range efficiently produces high-quality IQF products without compromising cost, footprint, or quality. Seamless integration into a continuous or automated production line is possible. It consistently delivers high-quality results while preserving the products’ nutritional value, shape, colour, smell, taste, texture and moisture level even after the end-user defrosts the product at home.

Coils provide excellent heat transfer with rapid and efficient water or hot gas defrosting, including an automatic defrosting system.

An evaporator with varying fin spacing eliminates the problem caused by product debris blocking the evaporator fins.

Infrequent and easy maintenance due to the robust construction and unrestricted access to all parts.

What options are available in the IQF Tunnel Freezers and Chillers Range?

What advantages does the IQF Tunnel range offer?

Versatile

- It is tailor-made to meet our customer’s requirements.

Scales production

A two belt system has significant advantages over a single one, like:

- Both belts can be programmed to operate at different speeds to suit the food product freezing requirements.

- Ability to scale production while maintaining the quality of food products.

- Both belts can be programmed to operate at different speeds to suit the food product freezing requirements.

- Provide a large capacity.

- Ability to scale production while maintaining the quality of food products.Crust freeze/fluidisation and hardening.

High quality & consistent results

- Consistently delivers high-quality results while preserving the product’s nutritional value, shape, colour, smell, taste, texture, and moisture level even after the end-user defrosts the product at home, thus extending the product’s shelf life.

- End users’ ability to defrost the quantity of product they require.

Hygiene Focussed

- Highest sanitation—equipped with food grade stainless steel with track cleaning as standard.

- Easy and complete access to all food contact surfaces.

- Efficient water drainage after cleaning.

- A belt washer or dryer and a Clean-In-Place system are available.

User friendly

- Customised level of control.

- Touchscreen panel, programming available in various languages.

- Ability to apply different programs per product.

- Eliminating the waste of portion sizes for end users.

- Variable belt speeds to suit the product freezing requirements.

- Coils in the IQF tunnel range have excellent heat transfer with rapid and efficient water or hot gas defrosting, including an automatic defrosting system.

- An evaporator with varying fin spacing eliminates the problem caused by product debris blocking the evaporator fins.

Reduces Waste

- Less product waste during the production process.

- Production labour.

- Energy and water.

Easily integrated

- A direct connection to a factory preparation or process system if necessary.

- Remote access and internet connectivity.

SImple Maintenance

- Infrequent and easy maintenance due to the robust construction and unrestricted access to all parts.

What advantages does the IQF Tunnel range offer?

Versatile

- It is tailor-made to meet our customer’s requirements.

Scales production

A two belt system has significant advantages over a single one, like:

- Both belts can be programmed to operate at different speeds to suit the food product freezing requirements.

- Ability to scale production while maintaining the quality of food products.

- Both belts can be programmed to operate at different speeds to suit the food product freezing requirements.

- Provide a large capacity.

- Ability to scale production while maintaining the quality of food products.Crust freeze/fluidisation and hardening.

High quality & consistent results

- Consistently delivers high-quality results while preserving the product’s nutritional value, shape, colour, smell, taste, texture, and moisture level even after the end-user defrosts the product at home, thus extending the product’s shelf life.

- End users’ ability to defrost the quantity of product they require.

Hygiene Focussed

- Highest sanitation—equipped with food grade stainless steel with track cleaning as standard.

- Easy and complete access to all food contact surfaces.

- Efficient water drainage after cleaning.

- A belt washer or dryer and a Clean-In-Place system are available.

User friendly

- Customised level of control.

- Touchscreen panel, programming available in various languages.

- Ability to apply different programs per product.

- Eliminating the waste of portion sizes for end users.

- Variable belt speeds to suit the product freezing requirements.

- Coils in the IQF tunnel range have excellent heat transfer with rapid and efficient water or hot gas defrosting, including an automatic defrosting system.

- An evaporator with varying fin spacing eliminates the problem caused by product debris blocking the evaporator fins.

Reduces Waste

- Less product waste during the production process.

- Production labour.

- Energy and water.

Easily integrated

- A direct connection to a factory preparation or process system if necessary.

- Remote access and internet connectivity.

SImple Maintenance

- Infrequent and easy maintenance due to the robust construction and unrestricted access to all parts.

How does the IQF Tunnel Freezer and Chiller Range operate?

Our IQF tunnel utilises a two-belt conveyor system designed for easy maintenance and cleaning to ensure efficient operation while consuming lower utilities. The in-feed belt of the system is employed to individually crust-freeze each product, preventing them from freezing together. The second belt facilitates an increase in the product depth for hardening, consequently reducing the overall system length. A two-belt system allows for a more compact configuration than a single-belt system, as both belts can operate at different and variable speeds.

What products does the IQF tunnel range support?

Our customers include market leaders in the food industry.

Enquire now

Thank you for reading about the Compact Spiral series from Korutek, experts in spiral freezing and cooling solutions.

Contact us to register interest, for a call back, or for a quote.

+44 (0)1603 672 455

info@korutek.com

Korutek Engineering Ltd

Centrum, Norwich Research Park,

Norwich, NR4 7UG

Spiral Cooling Systems

Global Spiral Freezer Specialists

Korutek are trusted around the world for providing bespoke spiral freezer builds, repairs, maintenance and consultancy. Our highly qualified team of engineers have several decades of industry experience working with many different brands on all kinds of freezing system projects.

Our clients know they can trust our specialists to have the right solution to any problem. Read our case studies to learn more.

New build enquiries

Korutek build spiral freezers and chillers for the biggest food manufacturers around the world.

If you’re looking for a team with a global reach that is able to provide industry-leading design and build services, contact Korutek today.

About Korutek Engineering

Korutek Engineering provide expert industrial spiral freezer and cooling solutions. Korutek is a global firm specialising in the design and build of new systems.

Korutek Engineering Systems

Korutek build spiral freezers and chillers for the biggest food manufacturers around the world. If you’re looking for a team with a global reach that is able to provide industry-leading design and build services, contact Korutek today.

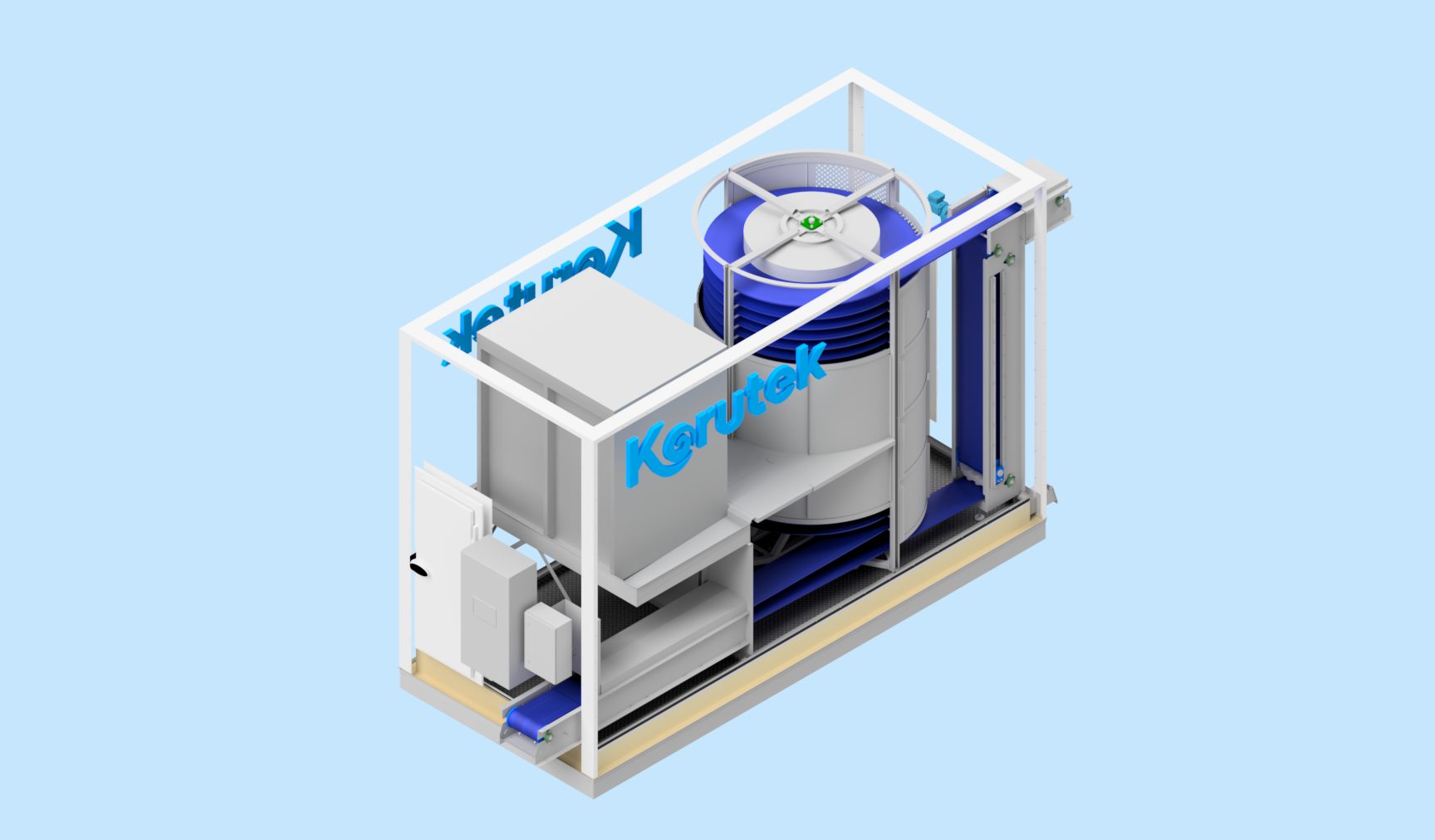

Compact Spiral Series

The Compact Spiral Series, consists of the 300 (CPS300), 450 (CPS450) and the 600 (CPS600) models.

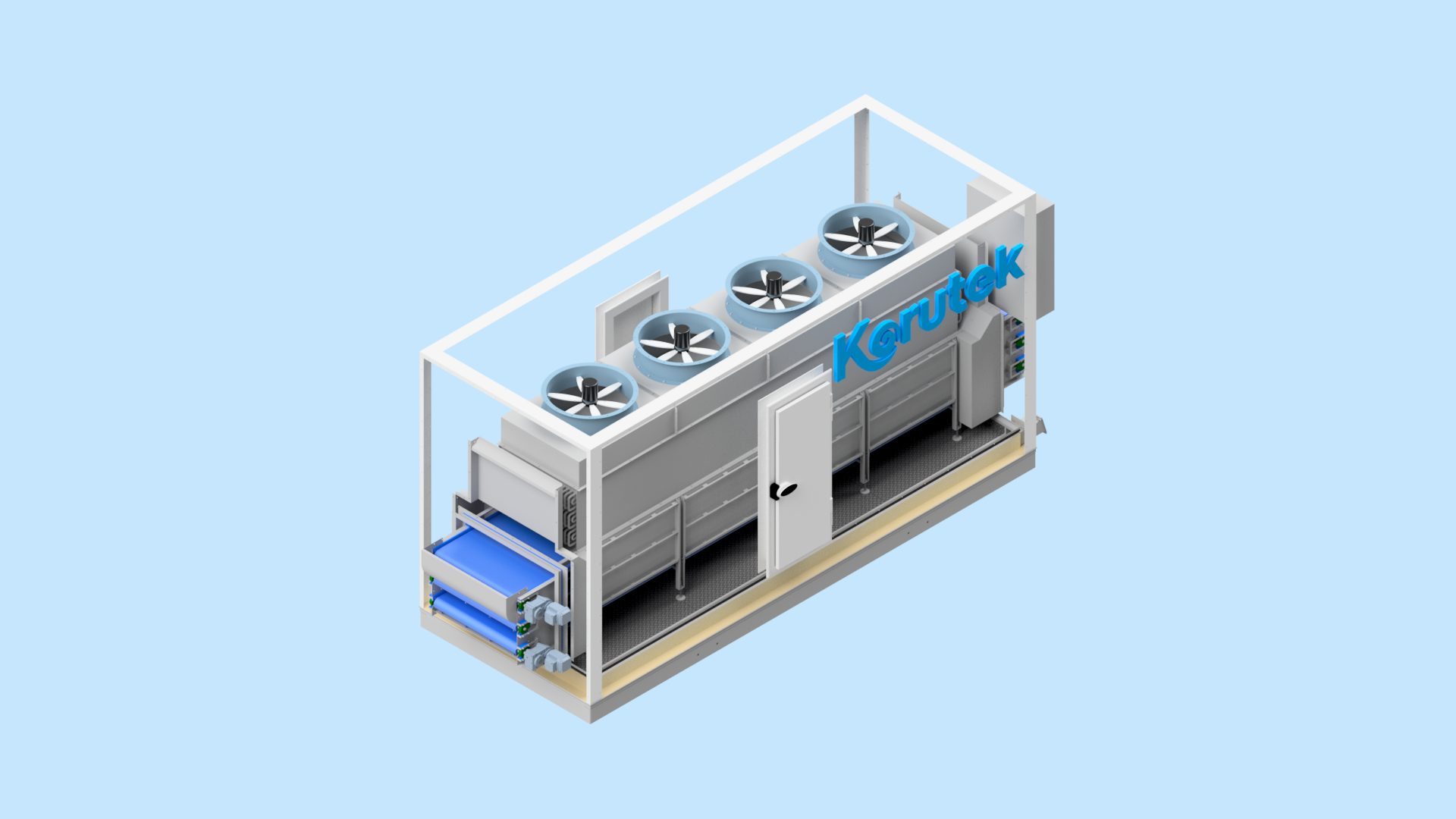

Compact Inline Tunnel

The system operates as one system using one, two or three separate inverter-controlled conveyor belts.

Spiral freezer systems

We are new system specialists, operating and consulting with the largest food industry manufacturers, all over the world.

Spiral chiller systems

Korutek Engineering are new spiral chiller specialists, operating and consulting with the largest food industry manufacturers.

Spiral cooler systems

We are new spiral cooler system specialists, manufacturing for and consulting with global food industry companies.

IQF freezers

We are an IQF freezer specialist, operating and consulting with some of the largest food manufacturers across the world.